Find the Z coordinate that the tool will be in while drawing and cutting. This is so crucial, I recommend doing it before every print. On my printer with the two-piece holder, the coordinates are minX=10, minY=8, maxX=192 and maxY=150, all in millimeters. Then locate the minimum and maximum XY coordinates of the available print area (make sure printer can move freely over it without bumping into any clips that you will use to hold the work in place).

#BEST INKSCAPE GCODE EXTENSION MANUAL#

Now, use your printer panel or software (I used Repetier Host) in manual mode to move the printhead around.įirst, move the printhead away from the bed for safety. If not, you will need to do some careful hardware/software working around. Make sure you can home your printer without the clip, holder or tool bumping into the bed. The calibration will be different for different combinations, and the Z-calibration will need to be done each time you level, as the heights will change slightly. If you're going to be cutting, level it very carefully.Īttach your clip and tool holder, and insert the tool you will use. Hence I designed my low-profile holder instead. The two-piece pen holder is really cool looking, but takes up a lot of space, which limits your print area. The nice thing about that is that the nuts then tend to stay in the hole. On my printer, these tend to come out very snug and I had to run a drill bit (sometimes just handheld) through the screw holes, and then use a screw to force a nut into the hole. There are screw nut holes that are printed by the file.

All of them are designed to use M3 screws and nuts to hold the tool in place.

The dimensions my pen holders are designed to hold up to a 15mm fabric marker, but you can use Thingiverse's Customizer to change the size. I used ABS juice (ABS dissolved in acetone) to attach the two piece holder to the attachment clip. You may need to change the dimensions slightly to fit your blade mount.Īs long as the mounting screw/glue holes on your attachment clip has the same placement as on mine, you should be able to just print my tool holders without change. The bird-shaped spring here is just designed to press on the blade mount's upper pin.

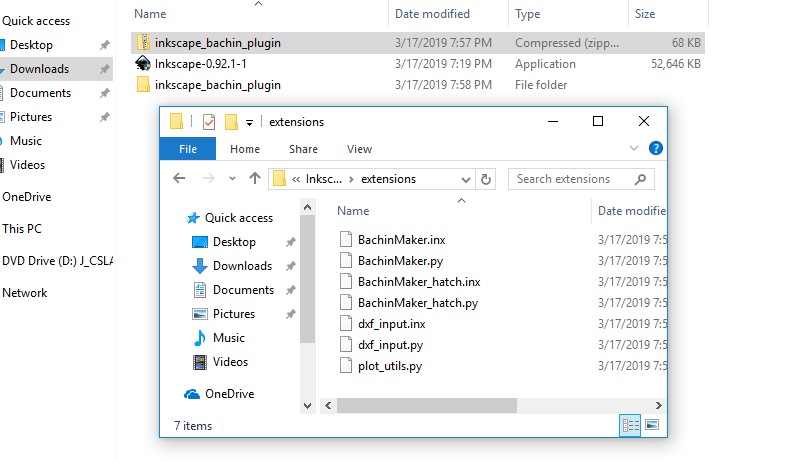

You may be able to use my OpenSCAD file to to customize for other printers. The attachment clip needs to be customized for your particular print head. The tool holder then screws or glues to it. The attachment clip provides a mounting surface, with screw holes or gluable mounting holes, that clips onto the print head. My total cost was under $20, not counting the printer.įor versatility and easy of printing, I went with a two-part approach: cutter holder and blades (I used this one) (for cutter).pins, plywood, screws and bungee cord (for extended print platform).The software side of this is a Python script / Inkscape plugin that I wrote to convert SVG / HPGL path files into gcode that the printer can print.

#BEST INKSCAPE GCODE EXTENSION MOD#

It was important to me that the printer mod be easily and quickly installable and uninstallable, so one can quickly switch between plotting, cutting and 3D printing.

0 kommentar(er)

0 kommentar(er)